For the safe and effective distribution of electrical wiring, cable tray is a must for any industrial or commercial establishment. They offer a dependable channel for the cables, easy maintenance and less hassle — all of which are important factors in satisfying strict safety requirements. For strong trays, you can click on the Best cable tray in India by MM Engineering Pvt. Ltd., A company Professionals Trust in Canada.

But choosing right type of electric cable tray and the right cable tray sizes can be a challenge. When you consider all of the countless designs, materials and how they even attach to the gate or door themselves, it would be a mistake to think that one size fits all due to relatively small chance of maintenance yet possible safety issues.

In this guide, we’ll take you through what you need to know about types of electrical cable tray, how to choose the right size and essential points to consider before installing.

1. Why the Right Cable Tray is so Important

Cable trays are not just a part of the support system, but due to their installed location and design, they provide important level of protection to cables against mechanical stress, humidity and also an overheating. A well-chosen tray ensures:

- Easy installation and maintenance

- Improved cable safety and lifespan

- Efficient space management

- Compliance with electrical standards

Industrial trays Regardless of whether you are installing an industrial project, a data center or a commercial building the perfect choice of tray ensures that operations remain efficient and safe.

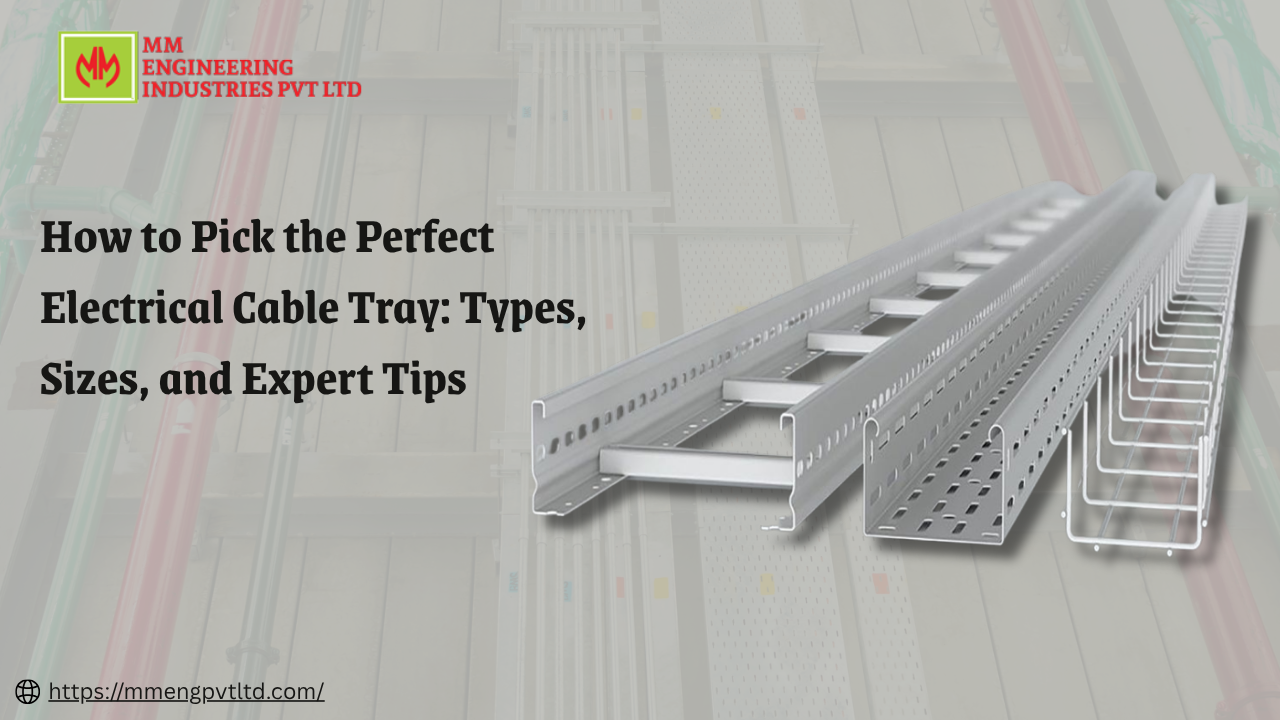

2. Types of Electrical Cable Tray

We’ll take a look at the most popular kinds of electrical cable tray, and which work best for different situations and wiring requirements below.

a) Ladder Type Cable Tray

Get Ladder cables are of the most common varieties, which have two rails running parallel and connected periodically by rungs.

Best for: Heavy duty cables with long runs, where air flow is necessary.

Advantages:

- Excellent ventilation prevents cable overheating

- Perfect for power and control cables

- Easy to modify and maintain

b) Perforated Type Cable Tray

This style has a slotted or holed bottom, so there is support but air also travels through it.

Best for: Industrial and commercial environments and electrical and instrumentation cabling.

Advantages:

- Cable Keep Cable Band For Dust Prevention

- Better aesthetic appearance

- Lightweight and easy to install

c) Solid Bottom Cable Tray

Unlike Lent Microgreen Trays, this one is solid without holes that gives you maximum security.

Best for: Delicate wiring, or places where there is high dust or moisture.

Advantages:

- Full cable protection

- Especially for the data cables and communication cables

- Prevents electromagnetic interference

d) Wire Mesh Cable Trays (Basket Tray)

There are forms that are flexible and can be easily cut or bent, for example those made of steel wire mesh.

Best for: Light-duty applications, IT rooms and small cable installs.

Advantages:

- Quick installation

- Lightweight and adaptable

- Ideal for underfloor cabling systems

e) Channel Type Cable Tray

Channel Tray: Compact and covered, channel trays are implemented when limited space is available.

Best for: Short runs of small-diameter cables.

Advantages:

- Economical and space-saving

- Neat appearance

- Reduces risk of cable damage

3. Understanding Cable Tray Sizes

Once you’ve decided what kind of tray you need for your job, the next decision is to choose the correct size cable tray.

Cable tray dimension, the sizes can be customized according to cable capacity and layout. A wrong size can result in either a jampacked or a sagging cable.

Here’s a quick guide:

Tray Width | Typical Application |

50–150 mm | Light control or communication cables |

| 200–300 mm | Moderate cable loads (commercial use) |

400–600 mm | Heavy-duty industrial cables |

| 800–1000 mm | Bulk cable grouping or For long distance application |

Pro Tip:

Select tray width which is more than 20% of extra space for future expansion. Cable capacity usually gets even larger as systems scale up so a bit of forethought can save a lot of reworking later.

4. Things To Consider Before Choosing a Cable Tray

Choosing the right tray is not a simple matter of type or size — it’s a matter of matching the tray to your project’s conditions and performance requirements. Here are some of the factors to consider:

a) Material

Types and materials Cable trays are available in different sizes or shapes, e.g. solid-bottom trays and channel trays. suppliers may offer other types of tray such as channel, wire mesh basket, conduit, etc. Cable-tray systems when compared to open wiring or electrical conduit systems provide many advantages or differences like the possibility of removing or adding cabling without having to remove existing cables.

- Steel trays are durable and strong.

- Aluminum pans are lightweight and will not rust.

- For use in the chemical and coastal environments, FRP trays are a good choice.

b) Load-Bearing Capacity

Be sure to always confirm max load capacity — in particular where industrial setups are concerned, with heavier and denser cables.

c) Installation Environment

Think about exposure to water, chemicals or high temperatures. The appropriate material and finish)* such as a galvanized or powder-coated one will not rust or degrade.

d) Future Scalability

Your electrical setup will evolve. Select trays that enable convenient cabling changes and additions so you don’t have to replace the entire system.

5. Tips from the Pros for Selecting Cable Tray Efficiently

- Design Before You Install: Draw out your pattern and locate bends, tees, and load points.

- Use Fittings, Clamps, and Covers: Right connections, clamps and shields are that ensure better protection and management for both the cables ends.

- Provide Ventilation: Power cables need an open environment to prevent overheating.

- Labor Safety: Always follow the latest IS and IEC guidelines in case of electrical installation.

- Work closely with a Dependable Supplier: Durable trays mean durability and efficiency, even in rigorous applications.

6. Why Select MM Engineering For Cable Trays

For stable and long lasting cable management systems, nothing can beat MM Engineering Pvt. Ltd. is known for their exceptional rebar-cutting performance, high-quality manufacturing, and precision design; as well as for well-rounded knowledge of construction market trends.

They carry a full line of Ladder, Perforated, Wire Mesh, Channel and Solid Bottom cable tray products to meet the needs of both their standard accounts as well as those with custom requirements.

Check out there entire product range here Best cable tray in India

If you’re in charge of a small commercial project or responsible for overseeing one of today’s complex industrial facilities, let MM Engineering get you just the right tray system — engineered to serve long and safely.

Conclusion

To ensure that you choose the right electrical cable tray, You need to know about the various types of electrical cable tray, the perfect cable tray sizes and how they meet your specific project needs.

With the right material, load capacity and also based on your environment, create a system to help you organize your cables for safety and efficiency.

For high-grade cable trays that perform on strength and integrity, rely on MM Engineering Pvt. Ltd. — your best source for imported the Best cable tray in India.